This turbojet engine technology is designed to enable supersonic flight at high gravitational and volumetric power density using electric plasma instead of hydrocarbon fuel combustion. This innovation from Georgia Tech offers the potential for a greatly reduced carbon footprint for air travel, while simultaneously lowering costs.

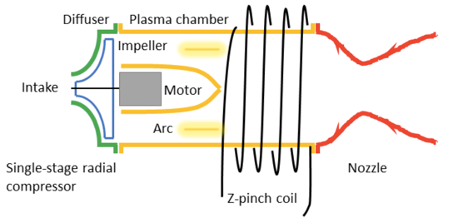

Unlike conventional turbojet engines, which are heated by the combustion of a hydrocarbon fuel, this method compresses and directs air into a plasma chamber where heat is added by electric plasma. The heated air is subsequently expanded through a de Laval nozzle to transform heat into supersonic flow and thrust by expanding the hot gas to match ambient pressure conditions. This invention addresses the challenges of existing technologies, such as lack of thrust potential, by featuring an integrated electric compressor able to run pressure ratios of 3-30, similar in power to conventional turbojet engines.

- Sustainable: This invention has the potential to replace costly hydrocarbon fuel with a sustainable and cost-effective alternative.

- Adaptable: Depending on the application, the plasma can be created and coupled by various means, including direct current electric arcs, radio frequency plasma, and microwave plasma.

- Cost-saving: This invention has the potential to replace costly hydrocarbon fuel with a sustainable and cost-effective alternative.

- Efficient design: To avoid the common problem of overheating the walls of the plasma chamber, this invention introduces a magnetic confinement that has the added benefit of allowing thrust vectoring of the jet.

- Powerful: This design could offer vertical takeoff and landing capabilities in addition to forward thrust using the same jet engine.

- Air travel, including passenger airplanes

- Space exploration

Electric flight, including concepts of plasma jet engines for supersonic and hypersonic applications, have the potential to sustainably decarbonize air transportation. Two of the biggest challenges, however, are energy storage and propulsion. Currently, there are several concepts for subsonic electric airplanes, but the propulsion technology for the supersonic electric flight regime has not been adapted adequately. In a closely related market, there are several concepts for non-electric supersonic passenger airplanes, however, they have no electric counterpart.

In order to compete with these concepts, new electric propulsion technologies are required. The propulsion for most concepts of future electric aircraft is based on ducted fans or propellers. In both cases, the torque is generated by electric motors. These systems have the advantage of relatively high propulsion efficiency and the ability to scale well for turbo-electric distributed propulsion. Their disadvantages, however, include low gravimetric and volumetric power density as well as a limited speed range. This is especially true for supersonic applications, where heating limits the efficiency, and shock waves stall the fan.

Conventional turbofan and turbojet engines, on the other hand, offer good power density and can be tuned to operate over a very wide speed range—even well into the supersonic regime—but require hydrocarbon fuel. A new type of propulsion technology is necessary to combine the ability to operate over a wide range of speed and altitudes while running on electric power.

Single-stage radial compressor configuration showing the conceptual design for a small-scale demonstrator engine

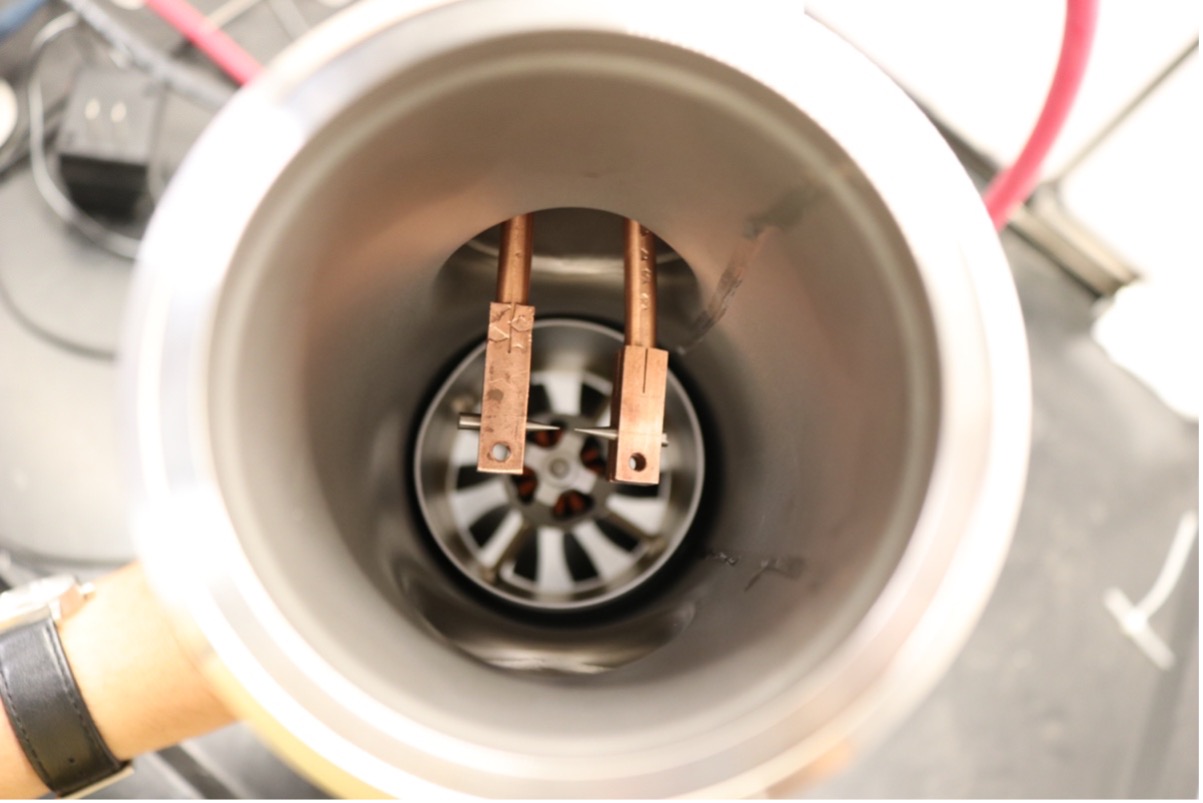

A demonstration system that allows researchers to test different electrode materials and geometries while characterizing the heat transfer into the high-speed airflow